Multi-Conductor Compatibility with Steam (Autoclave) and Gas Plasma (STERRAD®) Sterilization

Abstract

New England Wire Technologies Corporation has defined the sterilization compatibility of its proprietary jacket compounds used on ultra-flexible medical electronics cables. Two specialty silicone rubber compounds, NF11 and NF04, were evaluated for compatibility in both autoclave and the increasingly common STERRAD® gas plasma sterilization system developed by Advanced Sterilization Products (ASP). Additionally, a custom-formulated, matte-finish, thermoplastic polyurethane was evaluated for compatibility in the STERRAD® system.

Cables subjected to autoclave sterilization were evaluated for physical and visual changes every 50 cycles for 250 cycles. Both silicone jackets had useful physical properties at the end of the study, with specific properties predicted to retain over half their original value well beyond 250 cycles.

Cables subjected to STERRAD® gas plasma were repeatedly sterilized with minimal washing between cycles to create a “worst case” scenario for functional compatibility testing. Cables were evaluated for physical and visual changes every 25 cycles for 100 cycles. All three jacket materials demonstrated useful physical properties at the end of the study. Both silicone compounds are predicted to perform beyond 200 cycles, with potential enhancement using NEWtuf® construction. The specialty polyurethane offers additional stability with predicted usability for several hundred cycles.

Introduction

Medical electronics device designers require materials that can be expected to sustain repeated sterilization exposure. Steam sterilization through autoclave is a well-known method. Gas plasma sterilization through the STERRAD® system is more recently established but becoming more common. The study undertaken here provides quantified evidence of specialty materials tested for functional compatibility in their component form (extruded jacketed multi-conductors vs. traditional molded slabs).

Background

The steam autoclave is considered the oldest, safest, most widely used and most cost effective method of sterilization in the medical industry. Moist heat kills and destroys microorganisms by denaturing enzymes and structural proteins. Steam is produced in a pressurized chamber at temperatures between 121 and 148°C and pressure range of 15 – 30 psi. Time, temperature and pressure are dependent on each other, the size of the load, and condition of items (wrapping). There are two main types of autoclaves: gravity displacement and pre-vacuum cycle. This study employs a pre-vacuum autoclave. These high speed sterilizers are fitted with a vacuum pump to ensure all air is removed from the chamber and load before the steam is introduced. This significantly improves steam penetration.

A new sterilization method based using gas plasma was introduced in 1987 and marketed in the United States beginning in 1993. Gas plasma is produced in an enclosed chamber under a heavy vacuum using radio frequency radiation or microwave energy in order to excite gas molecules and produce charged particles in the form of free radicals. The process takes place in multiple phases, including transfer, diffusion, plasma, pump-down and vent for a total cycle time under 50 minutes. The by-products of the cycle are nontoxic. The process has a relatively low temperature range between 37 and 44 degrees Celsius. Materials and devices that are heat and humidity sensitive including plastics, electrical devices, and corrosion-susceptible metals can potentially be sterilized using hydrogen peroxide gas plasma.

Material Selection

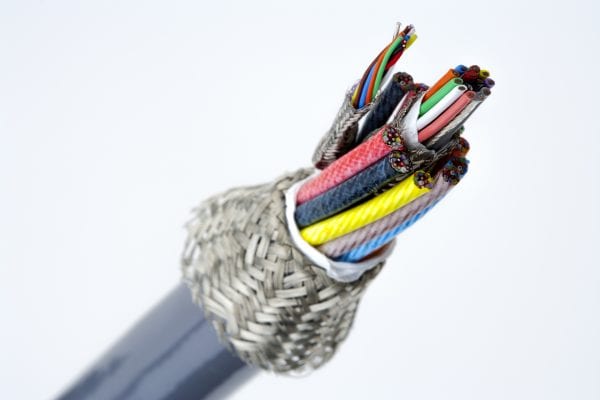

Medical electronics applications place a number of demands on modern materials. Cables for these devices must be biocompatible and flexible (maneuverable). They may also need to be small, lightweight and endure repetitive flexing or coiling. Anticipated sterilization methods may also impact material selection.

Silicone rubber is commonly selected for its superior flexibility and heat resistance (silicone, in thick molded parts, is known to have some autoclave stability). Many grades are available to meet demands for improved toughness, texture, flexibility and other properties. Two specialty grades of different chemistries were selected functional evaluation up to 250 autoclave cycles and 100 STERRAD® cycles.

Thermoplastic Polyurethane (TPU) is also commonly selected for biocompatibility, flexibility and superior durability. While it does not have the heat resistance of silicone, sterilization technologies such as STERRAD® eliminate the need for extreme heat resistance. NEWT selected a unique medical grade TPU alloy with low coefficient of friction matte finish for functional evaluation up to 100 STERRAD® cycles.

Autoclave Results

Cables subjected to autoclave sterilization were processed at 132C and 45 psig for 18 minutes, followed by an aeration period for a total cycle time of 40 minutes. Sterilized cable samples were tested in accordance with UL method 2556, Section 4: Insulation and Jacket Materials Test. Baseline samples were tested at each interval for comparison. Evaluations were made based on visual observations and physical measurements (dimensional, tensile and elongation). Cables exposed to autoclave sterilization were tested every 50 cycles for 250 total cycles.

One common method of assessing the service life of a material is to consider the point at which it is reduced to 50% of its original elongation. By this method, NF04 achieves 243 cycles while NF11 has a service life of 427 cycles. It is important to note that the cables included in this study were pulled from regular production runs with no special manufacturing processes or accommodations. The two cable designs are not identical. While both are relatively thin jackets under 0.040” the NF11 jacket has slightly more thickness than the NF04.

NF11 cables showed no visible defects; however, talc used as a release agent did become more prominently visible on the surface of the cable over the course of 250 cycles. This phenomenon was not observed on the NF04 jacketed cables; however the difference in color would have masked any talc on the surface of these cables. NF04 jacketed cables are also available without talc or other release agents.

STERRAD® Results

Cables subjected to STERRAD® gas plasma were processed by Advanced Sterilization Products (ASP) using the STERRAD® 100NX® standard cycle in accordance with AAMI TIR No. 12-2010. Each cycle received 59% nominal concentration hydrogen peroxide by weight. All cycles were performed with minimal washing of samples between cycles to create a “worst case” scenario for functional compatibility testing. Exposed cables were shipped to New England Wire Technologies’ development lab for testing in accordance with UL method 2556, Section 4: Insulation and Jacket Materials Test. Testing was conducted every 25 cycles for 100 total cycles.

It is common for material suppliers to describe exposure and aging performance based on the time it takes for a material to be reduced to 50% of its original property. Therefore, linear regression was used to model the results and predict the number of cycles required to reach 50% of the original baseline value. The exception is ND15 elongation, which increased during STERRAD® exposure. This situation is evaluated based on the number of cycles required to increase elongation to 150% of its original baseline value.

Conclusion

NEWT specialty silicone jacketed cables are well suited for reusable medical electronics that demand compatibility with autoclave and STERRAD® sterilization methods. Additionally, a custom- formulated, matte-finish, thermoplastic polyurethane has demonstrated functional compatibility with STERRAD® gas plasma sterilization.

This combination of biocompatibility, flexibility, texture and durability options will benefit applications including electrosurgical devices, instrumentation leads, surgical robotics, imaging devices, monitoring cables and more. Talc-free and reinforced silicone jackets such as NEWtuf® are available to enhance physical performance.

Acknowledgment

We would like to thank both Plymouth State University as well as ASP for the use of their equipment to complete this functional compatibility evaluation.

Article contributed by Rachel Brooks and Johanna Falkenham